Aqueous emulsion of ultraviolet-absorbing resin and emulsion resin composition

a technology of ultraviolet-absorbing resin and emulsion resin, which is applied in the field of aqueous (or water) emulsion of ultraviolet-absorbing resin and aqueous (or water) resin emulsion composition, can solve the problems of deterioration of transparency or mechanical strength in the aqueous emulsion resin, decrease in molecular weight, and decrease in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Examples

example 1

[0076] In a glass flask equipped with a cooling pipe, a nitrogen-introducing tube, a dropping funnel, a thermometer and a stirrer were charged 240 parts by weight of N,N-dimethylformamide (DMF) and 136.4 parts by weight of 1,1-bis-[3-(2H-benzotriazol-2-yl)-4-hydroxy-benzene ethanol]methane (trade name “MBEP”, manufactured by Otsuka Chemical Co., Ltd.), and the mixture was allowed to dissolve at 80° C. Then, 80.7 parts by weight of isophorone diisocyanate (IPDI) was added dropwise to the mixture under a nitrogen atmosphere with stirring, and the reaction was carried out for 2 hours. Further, 22.9 parts by weight of N-methyldiethanolamine was added dropwise thereto, and the reaction was continued for 4 hours.

[0077] Next, the reaction mixture was heated to 95° C. under a reduced pressure of 40 to 50 mmHg to remove 190 parts by weight of DMF from the reaction mixture, and diluted and dissolved with 240 parts by weight of methyl ethyl ketone (MEK). Then, 14.1 parts by weight of acetic a...

example 2

[0079] In the same device as Example 1, 240 parts by weight of N-methylpyrrolidone (NMP) and 136.4 parts by weight of the ultraviolet absorber MBEP used in Example 1 were charged, and allowed to dissolve at 80° C. Then, 80.7 parts by weight of isophorone diisocyanate (IPDI) was added dropwise to the mixture with stirring under a nitrogen atmosphere, and the reaction was carried out for 2 hours. Further, 22.9 parts by weight of N-methyldiethanolamine was added dropwise thereto, and the reaction was continued for 4 hours. The reaction mixture was heated to 95° C. under a reduced pressure of 40 to 50 mmHg to remove 190 parts by weight of DMF from the reaction mixture, and diluted and dissolved with 240 parts by weight of methyl ethyl ketone (MEK). Then, 14.1 parts by weight of acetic acid was added to the resulting mixture for quaternizing a tertiary amine portion in the resulting mixture. To the resultant was added dropwise 560 parts by weight of water to form an emulsion. Methyl ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

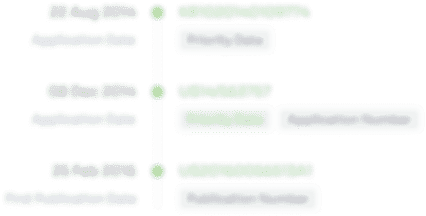

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com