Ice wine yeast with high fermentation activity and outstanding aroma-producing characteristics and application thereof

A yeast and ice wine technology, applied in wine preparation, alcoholic beverage preparation, microorganism-based methods, etc., can solve the problems of product homogeneity, indifference, lack of regional characteristics, etc., and achieve fast fermentation speed, short time, strong fermentation The effect of aroma production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Examples

Embodiment 1

[0019] Example 1, Saccharomyces cerevisiae (Saccharomycescerevisiae) No. YSL16010 isolation, purification and identification

[0020] The Vidal ice grape juice from the Huanren production area is placed in a small fermenter in the winery, and the unpasteurized Vidal ice grape juice is added to 80% of the volume, and the fermentation temperature in the fermenter is controlled by the cooling water circulation system. 16°C, internal circulation every 3 days, a total of 40 days of fermentation, sampling at different stages of fermentation, the fermentation is roughly divided into three periods: the first 10 days, the middle 20 days, and the last 10 days. Samples were taken every 2 days in each stage, and serially diluted (10 -4 ,10 -5 ,10 -6 ) after coating the WLN culture plate to obtain a large number of single colonies of wine yeast, from which 116 strains were selected that grew better in the plate, grew faster, had obvious morphological characteristics, and formed relativel...

Embodiment 2

[0040] Example 2. Comparative experiment on brewing effect of Saccharomyces cerevisiae YSL16010 and commercial yeast DV10

[0041] The comparison of the brewing characteristics of the screened Saccharomyces cerevisiae YSL16010 and commercial active dry yeast DV10 in Vidal ice grape juice, the specific methods are as follows:

[0042] The self-sieving wild-type Saccharomyces cerevisiae YSL16010 and the commercial Saccharomyces cerevisiae DV10 stored at -80°C were respectively passaged on YEPD solid and liquid medium, and 10 5 CFU / mL was inoculated in 3L Vidal ice grape juice, and cultured statically at 16°C for 40 days.

[0043] First, pick and culture the overnight self-sieving wild-type Saccharomyces cerevisiae and the commercial Saccharomyces cerevisiae DV10 control strain from the YEPD plate and insert them into the Erlenmeyer flasks containing 100 mL of sterilized liquid YEPD medium, shaker (180rpm, 28°C) Cultivate for 24 hours as the activated seed solution to be inocula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

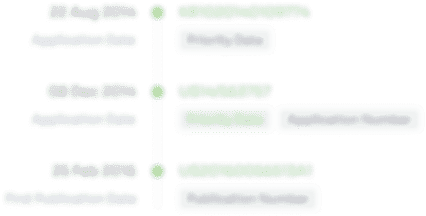

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com