Fiber foamed concrete and preparation method thereof

A fiber foam and concrete technology, applied in the field of foam concrete, can solve the problems of low compressive strength and poor durability of thermal insulation boards, and achieve the effects of good water absorption, improved integrity and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

[0025] The present invention starts from the durability of the railway subgrade thermal insulation material, combines the foam concrete which is widely used in the thermal insulation of building exterior walls, and comprehensively considers the durability and compressive strength, etc., and aims to design the fiber foam concrete with the most optimized performance. Applying foam concrete, which is widely used in building insulation, to railway insulation is very meaningful for railway construction and improvement of railway performance. While enhancing the compressive strength and flexural strength of foamed concrete, the fiber increases the porosity of the foamed concrete, that is, reduces the thermal conductivity, which greatly improves its thermal insulation performance compared with the foamed concrete. After single factor experiments and freeze-thaw cycle tests, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

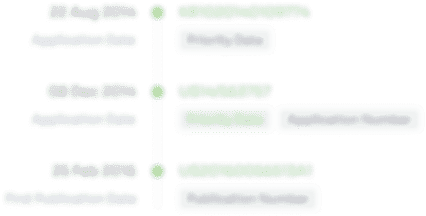

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com